Smokeless Woodstove for Improved Health

By Paul van der Sluis, Philips

Smoke generated by indoor cooking fires is identified by the World Health Organization as the killer in the kitchen (WHO report). More than 1 million people die yearly from indoor smoke-related diseases such as pneumonia and other acute lower respiratory infections. Exposure to smoke from biomass fuels impairs the self-defense of the lungs at multiple levels, and increases the risk of both tuberculosis infection and tuberculosis disease (PLOS Med., Volume 4, 2007, Issue 1, p. 174).

I have developed the cleanest wood-burning stove tested to date by the Aprovecho Research Institute. This stove has significantly lower toxic emissions during cooking than other wood stoves currently in use in developing countries. Widespread dissemination of this stove would be expected to reduce the incidence of smoke-related diseases and therefore improve respiratory health.

Smoke billows from a house as a result of an indoor fire

This project started off in a very unconventional manner. Several years ago I wanted to transform my household into one with a low CO2 footprint. For most functions in a household, a proper technological solution exists, but not for cooking. The garden of my house generates significant wood clipping from pruning of the trees. However, no clean, efficient, and practical device could be purchased to use these clippings for cooking. During trips to Nepal and India I learned that a primitive stove gives of lots of smoke, is not practical and wastes a lot of wood.

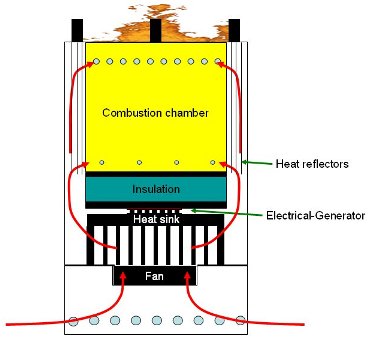

Cross-section of the woodstove

Health and environmental concerns have spurred a lot of research into clean cooking. With my background knowledge in chemistry, physics, and electronics, I selected what in my view was the best combination of technologies to create an efficient, clean, and easy-to-use cooking appliance that uses wood clippings as fuel. See the cross-section. For high efficiency, I enclosed and insulated the fire as much as possible. As a result, heat can escape only in the direction of the cooking vessel located above the fire. In a primitive stove, heat can escape in all directions. For clean combustion I added a fan to create an optimal airflow (see red arrows). A small amount of air is directed at the bottom of the fire, where it helps to vaporize the wood at the bottom of the combustion chamber (primary combustion). Most combustion air travels upward along the side of the combustion chamber where it gets preheated. This hot air is then blown at high speed into the combustion chamber where it burns the vaporized wood (the secondary combustion).

Photograph of the stove showing the gas-like flames from the secondary combustion

The result of this design is that flames have a shape similar to a gas flame. For added convenience I made a fan regulator so the fire power can be adjusted.

The project could have ended here, but I went to my employer Philips to explore possibilities for bringing this stove to the market for application in the developing countries. Philips has the capabilities to bring products to mass markets (half of humanity could benefit from this product) and has the ability to obtain user insights. Now embedded in a large organisation, the stove has transformed from a prototype into a product specifically for developing countries. Using Philips resources, I could also optimize the combustion for cleanliness and efficiency.

Many of the smoke and other emissions from improper wood combustion contribute more to global warming than pure CO2 emissions. That means that cleaner combustion lowers global warming, even if fuel use is not lowered, or if fuel use is irrelevant because the fuel is harvested sustainably. Because there are many people still relying on these solid fuels in combination with poor stoves, the effect is significant.

The stove can also be used to burn dung, charcoal, and crop residue, three popular fuels in developing countries. The crop residue has to be pressed into briquettes to avoid frequent fuel additions, but dung and charcoal can be used unmodified. However, from an environmental point of view the latter two can best be avoided. Charcoal is made with low efficiency from wood, frequently only 10% based on energy, which means than 10 times more wood needs to be cut down in order to satisfy the energy demand for cooking compared to using the wood directly. Charcoal is used because it is smokeless and convenient. This new woodstove offers the advantage of being smokeless and convenient, without the inefficient conversion of wood to charcoal. The woodstove lowers fuel use and therefore could also circumvent the use of dung, which should be left in the field because it is a fertiliser supplying nitrogen for plant growth.

Large scale dissemination of this stove can have a large impact on global warming, on deforestation, and on the health in developing countries. Philips plans to start sale of the woodstove in 2009.

- For more information on dissemination please contact:

- Hélène Mancheron

- Consumer Marketing Director Sustainability

- PHILIPS Consumer Lifestyle

- Piet Heinkade 55

- P.O.Box 850 1000 AW Amsterdam

- The Netherlands

- Phone: 31 20 59 78592

- Fax: 31 20 59 78926

- GSM: 31 (0) 6 22 47 00 05

- E-mail: Helene.mancheron@philips.com

- For technical information please contact:

- Dr. P. van der Sluis

- Philips Research Laboratories Eindhoven

- High Tech Campus 4

- 5656 AE Eindhoven

- Box WAG12

- The Netherlands

- Phone: 31 40 2742343

- Fax: 31 40 2746505

- E-mail: Paul.van.der.Sluis@philips.com